Steel Structure Hangars: Reliable and Spacious Solutions for Aircraft Storage and Maintenance

In the world of aviation, where precision, safety, and efficiency are paramount, the design of aircraft hangars plays a crucial role in operational success.

Airlines, maintenance companies, and private jet owners all require facilities that offer large clear spans, high durability, and minimal maintenance.

That’s why steel structure hangars have become the global standard for aircraft storage, maintenance, and service centers — offering unmatched reliability, flexibility, and cost-effectiveness.

1. The Importance of Aircraft Hangars

Aircraft hangars are more than shelters; they are high-performance engineering environments designed to:

- Protect aircraft from weather damage

- Enable safe maintenance and inspection work

- Provide storage and logistic management

- Ensure security and operational readiness

Given these complex demands, the structural design must meet strict international aviation standards, where steel provides the best solution.

2. Why Steel Structures Are Ideal for Hangars

Steel structures are widely used in the aviation industry because they combine engineering strength, rapid construction, and design adaptability.

a. Large Clear Span

Steel can achieve spans of 80–120 meters without interior columns — allowing aircraft to move freely inside.

b. Lightweight and Strong

Despite their strength, steel frames are lighter than concrete, reducing foundation loads and construction costs.

c. Rapid Installation

Prefabricated steel components ensure fast assembly, which is crucial for airport infrastructure projects with tight deadlines.

d. Long Service Life

With anti-corrosion coatings and minimal maintenance requirements, steel hangars can last over 50 years.

e. Sustainability

Steel is 100% recyclable, supporting green airport initiatives and environmental certifications.

3. Structural Design Overview

| Component | Description | Function |

|---|---|---|

| Main Frame | Welded H-section or portal frame steel | Structural stability |

| Roof System | Curved or sloped insulated panels | Weather and thermal protection |

| Wall System | Sandwich panels or aluminum cladding | Durability and aesthetics |

| Doors | Sliding, folding, or vertical lift | Aircraft access |

| Floor | Reinforced concrete slab | Load support |

| Cranes & Equipment | Overhead systems for maintenance | Operational support |

The structural layout prioritizes spatial efficiency, durability, and safety, meeting standards from ICAO and FAA.

4. Wide Span and Column-Free Design

One of the main advantages of steel structure hangars is their ability to provide massive open spaces without interior obstructions.

This allows:

- Easy maneuvering of large aircraft (Boeing, Airbus, etc.)

- Flexible maintenance and equipment layouts

- Safer working environments

Through advanced space frame or truss systems, hangars can reach clear spans of over 100 meters, suitable for both commercial and private jets.

5. Types of Steel Structure Hangars

a. Single-Span Hangar

Ideal for small and medium-sized aircraft.

Features simple structure, low cost, and fast installation.

b. Multi-Span Hangar

Used for large commercial fleets or maintenance operations.

Includes internal partitioning for workshops and offices.

c. Retractable or Movable Hangar

Designed for remote or military bases.

Features lightweight steel frames with easy assembly and disassembly.

d. Arch-Type or Space Frame Hangar

Architecturally stunning with enhanced strength and large clear spans.

Suitable for major airport hubs and national carriers.

6. Hangar Doors and Access Systems

Hangar doors are critical components engineered for both function and safety.

Common designs include:

- Sliding doors: cost-effective for medium-size hangars

- Vertical lifting doors: maximize space efficiency

- Folding doors: suitable for variable aircraft sizes

Steel frameworks support motorized door systems for quick operation and emergency response.

7. Fire and Safety Considerations

Aircraft hangars must comply with strict fire safety and structural integrity regulations.

Steel structures are inherently non-combustible and can be enhanced with:

- Fireproof coatings

- Emergency ventilation systems

- Lightning protection

- Sprinkler and foam extinguishing systems

This ensures personnel and aircraft safety in all operational conditions.

8. Environmental and Climate Resistance

Steel hangars can be designed to perform under harsh weather — from tropical humidity to desert heat or snow loads.

Features include:

- Anti-rust galvanization or paint systems

- Thermal insulation panels

- Drainage and snow-resistant roofs

- UV-resistant cladding materials

These ensure long-term resilience and minimal maintenance costs.

9. Speed of Construction

In aviation projects, time equals money.

Prefabricated steel hangars can be erected 40–60% faster than conventional buildings.

Key advantages:

- Off-site fabrication for precision

- Bolt-connected frames for quick installation

- Simultaneous roofing and interior work

Airlines can start operations sooner, minimizing downtime and maximizing investment efficiency.

10. Cost and Maintenance Comparison

| Factor | Steel Hangar | Concrete Hangar |

|---|---|---|

| Construction Time | 5–8 months | 12–16 months |

| Clear Span | Up to 120 m | Up to 40 m |

| Weight | Light | Heavy |

| Foundation | Low-cost | High-cost |

| Maintenance | Minimal | Frequent |

| Durability | 50+ years | 30–40 years |

| Environmental Impact | Recyclable | High carbon footprint |

Steel structures deliver lower life-cycle costs and better operational flexibility.

11. Integration with Modern Technology

Modern steel hangars are not just storage spaces — they are intelligent facilities integrated with digital systems:

- IoT-based temperature and humidity monitoring

- LED lighting control

- Solar panel integration

- Automated ventilation and fire systems

These innovations make hangars safer, smarter, and more energy-efficient.

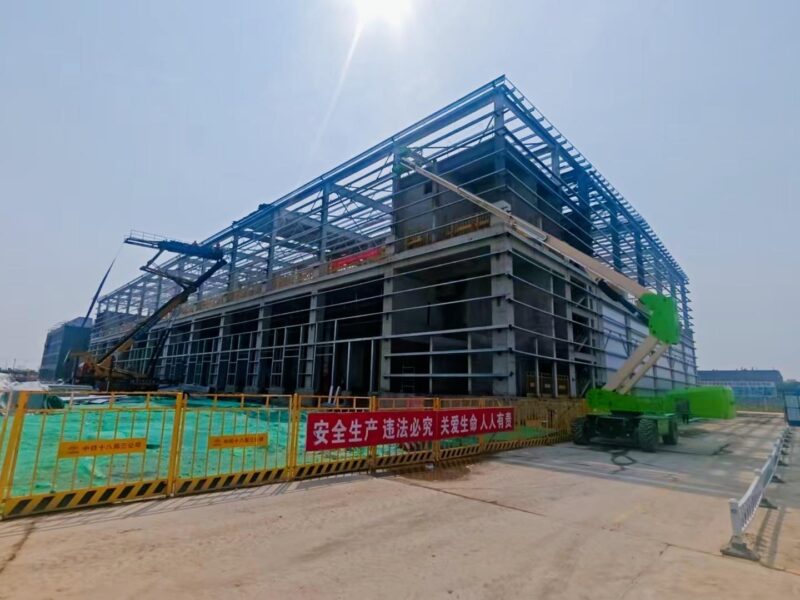

12. Case Study: Commercial Airline Maintenance Hangar

Project Overview:

- Area: 20,000 m²

- Clear Span: 100 m

- Structure: Space frame steel system

- Roof: Insulated sandwich panels with skylights

- Doors: Electric sliding system

- Completion Time: 6 months

- Result: 45% faster build, 30% energy cost reduction

This project highlights how steel structures meet the technical and functional demands of modern aviation facilities.

13. Sustainable Airport Infrastructure

As global airports aim for carbon neutrality, steel structure hangars support this transformation through:

- Recyclable materials

- Solar-ready roofing systems

- Natural daylight utilization

- Low energy consumption

Such features make steel hangars a key element in green airport development strategies.

14. Customization and Expansion

Steel hangars can be expanded or reconfigured as fleet sizes grow or operational needs change.

This scalability makes them ideal for:

- Commercial airlines

- Maintenance, Repair & Overhaul (MRO) centers

- Private aviation companies

- Military applications

With modular design, new sections can be added without disrupting operations.

15. Conclusion

Steel structure hangars embody the perfect balance of engineering precision, architectural functionality, and sustainability.

They offer:

✅ Massive column-free spans

✅ Fast and efficient construction

✅ Low maintenance and long service life

✅ Integration with smart and green technologies

For any aviation operator or airport authority seeking reliable, cost-effective, and future-ready infrastructure, steel is the ultimate material choice.

Steel builds the future of flight — durable, spacious, and sustainable.