Prefabricated Cow Sheds: Sustainable, Hygienic, and Cost-Effective Solutions for Modern Dairy Farms

The dairy industry is evolving rapidly, driven by global demand, automation, and sustainability goals. Traditional cattle housing often fails to meet modern production standards — construction takes too long, maintenance is costly, and conditions are difficult to regulate.

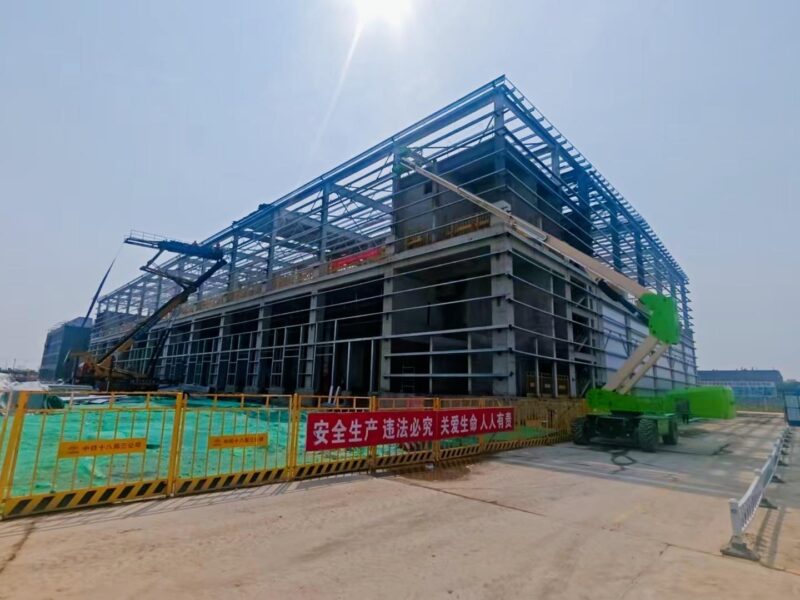

Prefabricated cow sheds have become a revolutionary solution for dairy farmers who want to combine animal welfare, hygiene, and efficiency in one modern facility. Designed with modular precision and built from durable steel structures, these sheds provide superior comfort for cows while reducing operational costs and environmental impact.

Why Prefabricated Cow Sheds Are the Future of Dairy Farming

Prefabricated construction allows all key components — structural frames, roofing, and panels — to be manufactured in a controlled environment and assembled quickly on-site.

This process ensures consistent quality, fast installation, and lower waste. More importantly, it provides flexibility to integrate modern farming technologies such as automated feeding, milking systems, and climate control.

With prefabricated sheds, dairy operations can scale up efficiently while maintaining high hygiene and productivity standards.

Key Advantages of Prefabricated Cow Sheds

- Fast and Efficient Construction

Prefabricated systems reduce on-site labor and installation time by up to 60%, allowing faster project completion and earlier milk production. - Animal Comfort and Health

Good ventilation, insulation, and drainage ensure a stable and clean environment — reducing heat stress, infections, and injuries among livestock. - Sustainability and Energy Efficiency

The use of recyclable materials, solar energy options, and efficient lighting reduces carbon footprint and energy costs. - Durability and Low Maintenance

Steel structures resist rust, corrosion, and pests, guaranteeing long service life with minimal upkeep. - Hygienic Design

Smooth wall and floor surfaces make cleaning and disinfection easier, which helps prevent bacterial contamination and supports better milk quality. - Scalability and Flexibility

Modular designs can easily be expanded as herd sizes grow or farm layouts evolve, without disrupting daily operations.

Applications of Prefabricated Cow Sheds

Prefabricated sheds can be customized to serve various functions within the dairy operation, including:

- Milking Parlors: Integrated milking systems for efficient and hygienic production.

- Resting and Feeding Areas: Spacious layouts with proper ventilation and bedding.

- Calf Barns: Controlled environments for young livestock development.

- Storage Units: Dedicated spaces for feed, hay, and equipment.

- Manure and Waste Management: Systems for drainage, cleaning, and composting.

Design Considerations for B2B Clients

When planning a prefabricated cow shed, B2B investors and farm owners should consider:

- Ventilation Systems: Natural or mechanical systems to control humidity and odor.

- Thermal Insulation: Keeping cows comfortable across seasons to boost milk yield.

- Flooring Solutions: Non-slip, washable surfaces that ensure safety and hygiene.

- Lighting and Energy: LED and skylight integration for cost-effective illumination.

- Automation Compatibility: Space for robotic milking and feeding systems.

Case Studies

- Dairy Farm in Denmark:

A 2,000 m² prefabricated cow shed was completed in 25 days, reducing construction costs by 35% and improving milk yield by 15% due to better environmental control. - Large-Scale Operation in Kenya:

Modular steel sheds provided durable shelter for 500 cows, significantly lowering heat stress and disease outbreaks. - Family Farm in Argentina:

Prefabricated components allowed a small farm to double capacity within three months without interrupting production.

Why B2B Clients Choose Prefabricated Cow Sheds

For investors, agricultural developers, and dairy cooperatives, prefabricated sheds offer measurable business benefits:

- Rapid project delivery and faster ROI

- Reliable quality control from factory production

- Easy maintenance and long lifespan

- Energy savings through modern insulation and solar systems

- Adaptable layouts for herd expansion or automation upgrades

- Compliance with global animal welfare standards

Prefabricated cow sheds deliver the perfect combination of technology, comfort, and sustainability — essential for the future of dairy farming.

Conclusion

The future of dairy farming lies in smart, efficient, and sustainable infrastructure. Prefabricated cow sheds are not just buildings; they are engineered systems designed to improve productivity, animal welfare, and operational efficiency.

For B2B investors and modern farmers, adopting prefabricated solutions means gaining a competitive advantage — faster construction, cleaner environments, and higher yields.

Strong, scalable, and sustainable — prefabricated cow sheds are the cornerstone of the next generation of dairy operations.